Secret specs for longer-lasting paddles

No one wants to buy a new paddle only to have it chip, break, bubble or develop dead spots within a few months. Yet many pickleball players have experienced these problems. What causes these issues, and is there any way to avoid them?

Luckily, there is! Aside from dedicating time to basic upkeep, the biggest precaution you can take is buying a paddle that follows solid design practices. The thing is, the most important factors in paddle construction aren’t written on a spec list or visible to the naked eye.

Here at PickleballCentral we know that beauty lies beyond the (paddle’s) surface. Let’s take a look at some hidden features that can literally make or break your equipment, beginning with the handle.

Handles

Handles can be made up of two wood pallets held together by staples and/or an adhesive. The problem is that these can weaken over time, causing the handle to come loose and twist during play. Some manufacturers use composites or even foam instead of wood, but these materials can suffer from the same stability problems.

Unique Construction

One company that has stepped away from traditional handle design is GAMMA. With the 2015 release of their three premium paddles, the Voltage, Atomic and Ion, GAMMA created a special Unibody Handle that functions just like it sounds. Rather than using pallets, the handle is made of a single molded piece connected to the paddle’s face.

Not only does this eliminate the problem of wobbly handles, but it provides a pleasing touch sensation and more durability in the long-term. This is a first in the industry and will certainly lead to fewer paddles breaking at the face/handle divide.

Stronger Pallets

That’s not to say all palletized handles are simply waiting to fall apart. Another manufacturer attempting to reduce these issues is Whippersnapper. While they do use a pallet-based design, the handle material on their KLX is reinforced with the same sturdy Kevlar present on the face. They also run the handle as far up into the face as possible to add increased stability.

The materials used for pallets also play a major role in their hardiness. Whippersnapper, for example, uses high-end basswood.

In comparison to another wood used in the pickleball industry, balsa, basswood is less likely to warp. Even though balsa is lightweight and sturdy, if it comes into contact with moisture, this can affect its weight and structure. While the handle will almost always be covered by a grip, over time it can break down from humid or wet playing conditions that manage to seep in.

A plastic handle will generally be more water-resistant than wood, but the sun plays a role as well. Some plastics will soften, warp and break down in UV light. It’s a good idea to avoid leaving your paddle outside for long periods of time whether you frequent warm or wet locales to avoid degradation.

Example of a palletized handle that just didn’t make it; you can see how the core material runs through the center

Cores

One of three core types are frequently used in pickleball paddles: Nomex, aluminum or polymer. For years a honeycomb structure has been the industry standard due to its light weight and durability.

Nomex

Nomex is an aramid fiber that has a high strength to weight ratio and is very heat resistant. It’s used in the aerospace industry and known to be very durable. Without getting into an engineering discussion, the reason it’s frequently used in graphite paddles is because it bonds well with graphite when exposed to heat during the manufacturing process. This helps solidify the structure and prevent the core from delaminating from the face, which is what causes “dead spots.” It is the most expensive core material.

Aluminum

Aluminum is similarly light, durable and heat resistant. Its ability to withstand repeated impact is slightly higher than Nomex, though Nomex paddles can reduce this problem by having a thicker face. Aluminum is not often used in graphite paddles because of the aforementioned difference in thermal expansion. Aluminum can actually corrode (rust) carbon fibers as well. This issue is largely avoided, however, by that fact that most graphite faces have some sort of protective coating on top of them to separate direct contact between the core and face.

Polymer

The polymers used in paddle cores are plastics, and are currently the lightest materials available at the lowest cost. Some players worry about their ability to withstand heat, but thankfully paddle manufacturers have taken steps to avoid sun-related troubles. Paddletek’s Phoenix Pro, for example, has a polymer core that is covered in a UV-protected outdoor vinyl, followed by a polycarbonate over-laminate. Paddletek is currently one of the only manufacturer to offer a 5-year guarantee against dead spots, yet all of their cores are made of polymer. Clearly there are bonding techniques that make a difference!

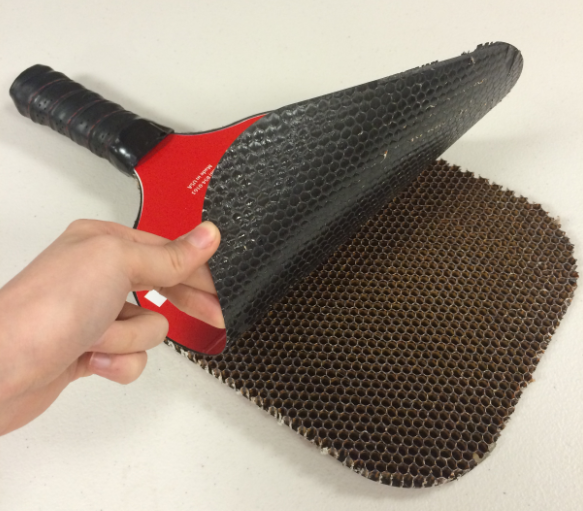

A paddles’ honeycomb structure revealed

Supportive Structures

The first paddle we know of that changed up the traditional core structure is Manta’s 4G. While it retains the familiar honeycomb design, there is an additional “soup” of composites that have been injected along the edge of the core. This helps provide extra balance, support and durability.

GAMMA features a somewhat similar idea in their premium paddle line with their Live Periphery Frame. Instead of composites, however, they created a tubular channel that borders both the paddle’s face and handle. This acts as a frame of sorts, allowing for an increased sense of control and dead spot reduction.

Edge Guards & Face Finishings

Most pickleball players know that paddle faces are made of two main materials: graphite and composites. Some manufacturers are also starting to experiment with more unique materials, such as the Kevlar used in Whippersnapper’s KLX.

Graphite is very solid but more brittle in comparison to composites, so it’s important your paddle has a good edge guard to protect against damage.

Edge Adhesion

Speaking of which – edge guards vary in quality just like every other paddle part. Plastic guards are more likely to crack than rubber, and how they are bonded to a paddle will determine whether they stay strong or eventually loosen and come off.

Guards are usually attached with pins, glue and other adhesives. Whippersnapper uses a special heat shrink process where the guard is put on the paddle warm, and as it cools it bonds to the paddle and seals the edges.

The seal between the edge guard and paddle face is very important as it helps protect the core material from environmental damage. In GAMMA’s case, since they feature a Flush-Fit Bumper that is in line with the paddle’s surface, they’re able to use the same epoxy that clear-coats the paddle face on top of the guard.

Finishings

While it’s simple to say that paddles are made up of either graphite or composites, the truth is that there are a wide variety of sealants used on top of these materials that go into making a completed paddle.

Epoxy is a finishing compound that is water resistant and strongly adheres to paddle surfaces. It’s more expensive than polyester resin/urethane, but it’s also more likely to hold up in heat. Polyvinyl overlays are used either by themselves or over the surface of the aforementioned materials. Some paddles also include UV inhibitors to help prevent structural damage and discoloration caused by the sun.

One of our resident pros, Brian Ashworth, says that he likes when paddles get discolored in a specific spot because it shows you’ve been playing consistently. He’s weird.

Summary

There’s a ton of hard work and creative technology that goes into paddle creation, far more than most players realize! Thankfully for us, manufacturers are always innovating and working to develop even more impressive designs. At PickleballCentral we try and provide our customers with as much relevant information as possible in our product descriptions, but if you ever have a more in-depth question regarding these rarely-mentioned specs, feel free to ask us or your paddle manufacturer for more information.

Share Product:

SHARE THIS: